China Prototyping Manufacturing: Pioneering Quality in Metal Fabrication

In the fast-paced world of technology and product development, the demand for rapid prototyping has never been higher. As businesses strive to bring innovative products to market, the significance of efficient and precise prototyping has become paramount. China prototyping manufacturing stands at the forefront of this industry, offering unparalleled advantages that can propel companies towards their goals.

Understanding Prototyping in Manufacturing

Prototyping involves creating a preliminary model of a product to test concepts and iterate designs before full-scale production. This crucial step in the development process allows businesses to:

- Identify potential issues early in the design phase.

- Reduce time-to-market.

- Enhance product quality through iterative feedback.

- Limit costs by minimizing material waste.

Why Choose China for Prototyping Manufacturing?

China has emerged as a global leader in manufacturing, particularly in the realm of prototyping. Here are several compelling reasons why businesses should consider leveraging China's manufacturing capabilities:

1. Cost-Effectiveness

One of the primary reasons companies turn to China prototyping manufacturing is the cost savings associated with production. Labor costs in China are significantly lower than in many Western countries, which allows businesses to produce high-quality prototypes at a fraction of the expense. Additionally, the availability of raw materials at competitive prices contributes to this affordability.

2. Advanced Technology and Infrastructure

China boasts some of the most advanced manufacturing technologies in the world. Facilities equipped with state-of-the-art machinery enable precision engineering and high-quality output. Companies like DeepMould.net leverage these technologies to deliver exceptional prototypes that meet stringent industry standards.

3. Skilled Workforce

With a vast pool of skilled engineers and technicians, China's workforce is capable of driving innovation and efficiency in manufacturing. These professionals are well-versed in contemporary design processes and are adept at using advanced manufacturing equipment, ensuring high-quality results.

4. Speedy Turnaround Times

In today’s competitive market, speed is truly of the essence. Chinese manufacturers are renowned for their ability to deliver prototypes swiftly without compromising quality. Rapid prototyping services are particularly beneficial for businesses that need to iterate designs quickly based on market feedback.

The Prototyping Process Explained

The china prototyping manufacturing process typically follows several key stages:

Step 1: Ideation and Design

This initial phase involves brainstorming product ideas and translating them into actionable designs using CAD (Computer-Aided Design) software. Experienced designers can create accurate digital representations of your product, which lays the foundation for prototyping.

Step 2: Material Selection

Choosing the right materials is critical to the success of the prototype. Factors like strength, weight, and finish must be considered. With a plethora of materials available in China—from metals to plastics—companies can select options that best fit their product requirements.

Step 3: Prototype Creation

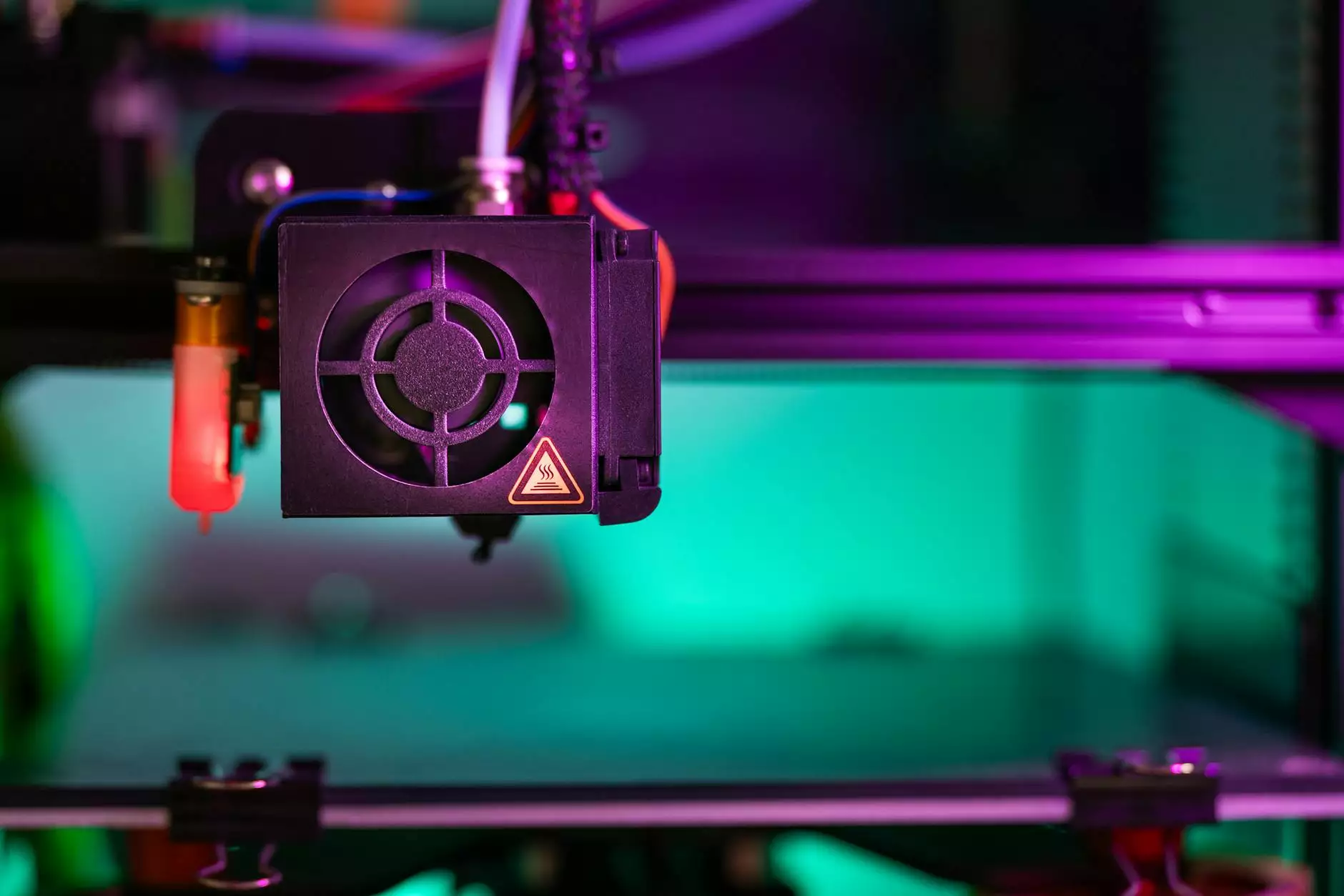

Using advanced manufacturing techniques such as CNC machining, injection molding, or 3D printing, prototypes are produced based on the approved designs. Each method has its advantages, and the choice will depend on the prototype's complexity and intended use.

Step 4: Testing and Evaluation

Once the prototype is created, rigorous testing ensues. This stage is vital for identifying shortcomings and gathering insights that can be used for improvements. Feedback is critical as it informs subsequent design iterations.

Step 5: Final Iterations

After evaluating the initial prototype, engineers make necessary adjustments to enhance the design. This iterative process may repeat several times until the prototype meets the designated standards and specifications.

Industries Benefiting from China Prototyping Manufacturing

The versatility of China prototyping manufacturing allows various industries to reap its benefits. Here are some sectors where rapid prototyping is invaluable:

- Aerospace: Prototyping in aerospace is vital for testing and refining complex components that adhere to stringent safety regulations.

- Automotive: The automotive industry relies heavily on prototyping for developing new vehicle designs, enhancing efficiency, and ensuring safety.

- Consumer Electronics: Prototyping aids in the swift development and iteration of electronic devices, ensuring they meet consumer demands.

- Medical Devices: Creating prototypes for medical devices requires precision and adherence to regulatory standards, making the process crucial for innovators.

- Furniture: Prototyping allows furniture designers to visualize and test aesthetics and functionality before mass production.

Choosing the Right Manufacturing Partner

Selecting a reliable partner for china prototyping manufacturing can significantly influence your project's success. Here are some tips for making the right choice:

1. Evaluate Expertise and Experience

Look for manufacturers with a proven track record in prototyping. Review their portfolios to gauge the quality of their work and their experience in your industry.

2. Assess Technology and Equipment

A manufacturer’s capabilities in terms of technology and machinery play a crucial role in the quality of the prototype produced. Ensure they use the latest equipment and techniques relevant to your needs.

3. Consider Communication and Support

Effective communication is key to a successful partnership. Your chosen partner should be responsive and willing to collaborate closely throughout the prototyping process.

4. Review Client Testimonials

Client feedback can provide insights into a manufacturer’s reliability and quality of work. Look for reviews and testimonials that speak to their performance and customer service.

5. Discuss Customization Options

Each project is unique; therefore, it’s essential to discuss customization options with your manufacturing partner. A good manufacturer will be flexible and willing to accommodate specific requests.

Future Trends in Prototyping Manufacturing

The landscape of china prototyping manufacturing is continually evolving. Here are some trends that are shaping the future:

1. Increased Adoption of 3D Printing

3D printing technology is revolutionizing the prototyping process, making it more accessible and cost-effective. As materials and techniques advance, the range of products that can be prototyped grows exponentially.

2. Sustainability in Manufacturing

With an increasing focus on sustainability, manufacturers are seeking eco-friendly materials and processes. This shift towards sustainable manufacturing practices not only helps the environment but also resonates with eco-conscious consumers.

3. Integration of AI and Automation

Artificial Intelligence (AI) and machine learning are beginning to play a significant role in design and prototyping. Automated systems can analyze data, suggest design improvements, and streamline the production process, enhancing efficiency.

4. Collaborative Design Platforms

As globalization continues, more companies are seeking collaborative platforms that facilitate joint prototyping efforts across borders. These technologies enhance communication and improve the overall design process.

Conclusion

China prototyping manufacturing stands as a beacon of innovation and efficiency in the modern manufacturing landscape. With cost-effective solutions, advanced technologies, and a skilled workforce, businesses can leverage China's capabilities to bring their ideas to life effectively. As the industry progresses, embracing new technologies such as 3D printing and AI will be crucial for staying competitive. By choosing a reputable partner like DeepMould.net, you can ensure the successful realization of your prototypes, paving the way for groundbreaking innovations.